At Hübner Giessen we work on solutions day in and day out to make difficult tasks in the heavy-duty sector simpler. Our electronic position switch ERC 40 provides a good example; not only does it replace mechanical rotary cam limit switches, but it also offers useful additional functions at the same time.

A lack of accuracy, standstill, maintenance costs, setting up work, start-up time and effort, servicing costs, disruption to the value creation chain and high overheads. You don’t think that sounds particularly positive? Neither did our customers think so either. However, they were precisely the problems confronting two of our customers operating in the fields of steel and rolling mills as well as open cast mining.

Our solution:

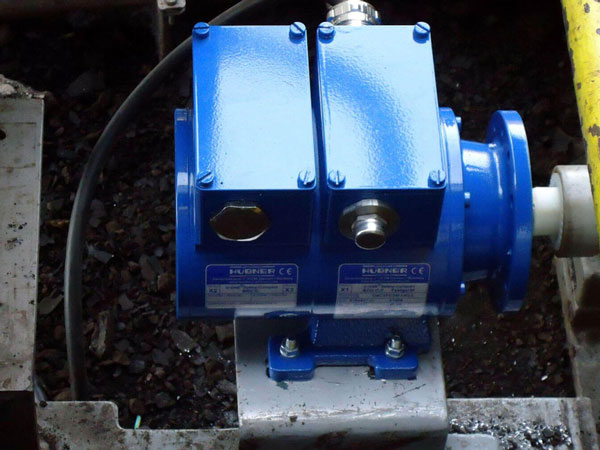

The ERC 40 was the solution to the problems in both cases. By replacing the existing mechanical solutions we were able to significantly simplify setting the switching points in the rolling mill. The customer moves the screwdowns to the desired position at which he wishes to set a switching point – and then transmits the information to the parameter assignment software per mouse click. If desired, it is possible to simply copy the saved switching points, for example following maintenance work or after replacing a device. Furthermore, eliminating the need for distribution gears combined with the greater precision of the ERC 40 has significantly increased the accuracy of the whole system. More information in our case study.

Replacing existing mechanical limit switches limiting the end position of moving plant components on a large open-cast mining machine have resulted in similar benefits. Enclosing the ERC 40 in a rugged casing to withstand extreme ambient conditions means the customer is able to profit from lower maintenance costs and reduced downtimes in addition to greater switching accuracy when approaching end position limits. User-friendly calibration via preset inputs, the ability to save and import parameter data sets, time-saving safety tests (switch test function) and integrated status monitoring round off the many benefits offered by the ERC 40. More information in our case study.

These are just two examples of how the electronic position switch ERC 40 simplifies the daily work load in the heavy-duty sector. We would be pleased to explain how you too can profit from the intelligent solution made in house at Hübner Giessen. Contact us.