The conveyor bridges weighing thousands of tons that are used in open-pit mining are some of the largest machines in the world. Despite their size, it is important that they run like clockwork, especially in terms of uniformity and precision. With tailor-made modernization measures, such requirements can also be met by older systems. The new Hübner Giessen Case Study reveals the advantages of converting mechanical position switches to electronic solutions.

When things are no longer running smoothly

When it comes to huge systems such as conveyor bridges, the position and speed of the many individual movable components need to be perfectly coordinated. If older mechanical position switches are used to meet this requirement, inaccuracies are just one of several problems users may face. Such switches often also require time-consuming servicing involving high maintenance costs and do not always have all required safety approvals.

Many problems, one solution

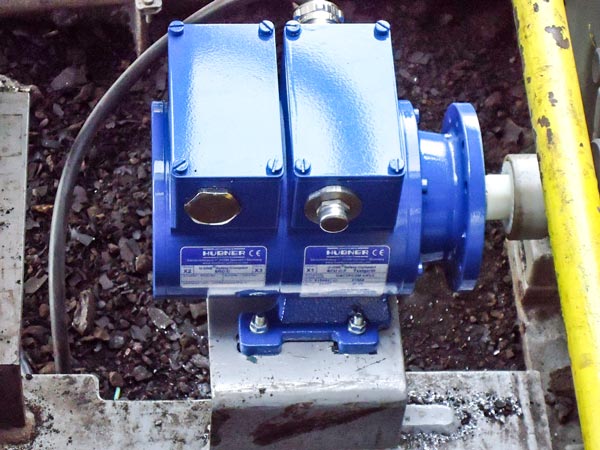

Electronic position switches from Hübner Giessen solve these and other frequently occurring problems. In a conveyor bridge used in open-pit mining, for example, we recently replaced the mechanical cam limit switches for limiting movement and end positions on hoists and slewing gears with an electronic position switch. You can read all about how this solution optimized precision and safety and made maintenance even easier in our Case Study: “Conveyor bridge / hoist: achieving higher precision and reducing costs and complications by converting from mechanical to electronic position switches”.