Many rolling mills face a recurring problem: the front motor of their tandem drives is often not equipped with a free shaft end for the speed sensor. This gap leads to synchronisation problems and increased maintenance costs. In our case study, we present a customised complete solution that addresses precisely these difficulties.

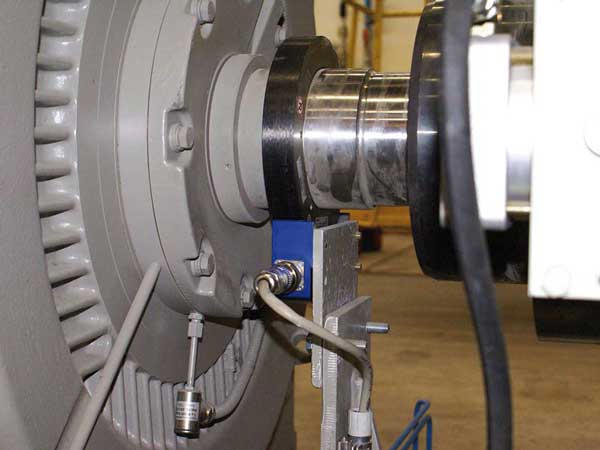

Flexible mounting thanks to half-shell design

Our magnetic encoder, specially developed for tandem drives in rolling mills, offers an innovative answer to this challenge. Thanks to its unique design consisting of two half-shells, it enables simple mounting directly on the motor shaft without the need for a free shaft end. This system not only offers flexible mounting options and protection against wear, but can also be easily integrated into existing systems.

Find out more about this specific project in our case study.

You can find detailed information about our MAG-G, the benefits and possible applications on the product page.