“I am sorry. But that device is no longer available.” Something along those lines or similar is how the answer can sound when mechanical rotary cam limit switches installed on cranes, with or without an aged PLC, have been discontinued or are no longer available for other reasons. And, what now? The solution can either be complicated and expensive – or you can give us a call. The reason is we have developed a simple solution to raise the monitoring of positioning ranges to be on a par with the latest state-of-the-art technology, without any further conversion measures.

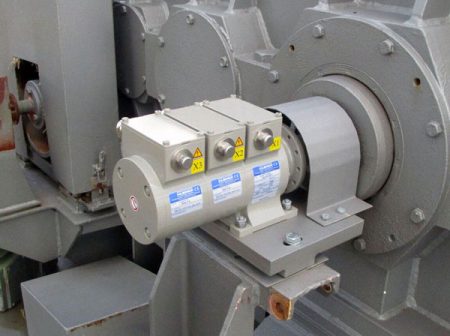

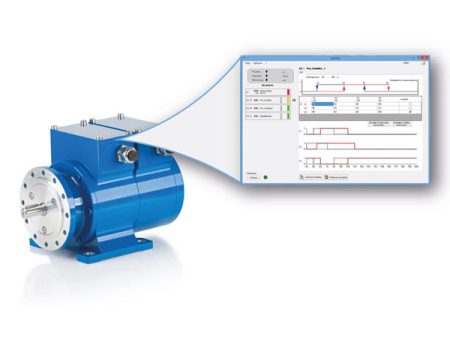

That is made possible by our electronic position switch ERC 40, with which it is as easy as pie to program switching points per software via a graphic interface to suit requirements. Essential for crane operators: Even external effects resulting in shock and vibration do not alter the switching points; they remain saved in the ERC 40. Moreover, we continued to remain focussed on the problem, with the result: it is still possible to continue to utilize the cabling for frequently used 230 V contacts. And because we think things should be made simple, you can also use the ERC 40 without having to convert to a (new) PLC at the same time. In addition, the ERC 40 offers a suitable exchange system for many cranes and attachment positions to allow you to remain as flexible as possible.

With the ERC 40 we have found an answer to the problem of replacing mechanical rotary cam limit switches on cranes. Contact us if you are also looking for an uncomplicated solution to upgrade your crane system. Or visit us at the TOC Europe 2018 from 12-14 June in Rotterdam. We would be more than pleased to demonstrate to you – at the leading trade fair for port, shipping and terminal technology – just how our solutions made in Giessen ensure robust and durable plant availability across the globe.