Description

MAG individual: Customized design and construction

MAG 200S: Standardized, available at short notice

MAG Incremental / MAG 200S

MAG individual: Customized design and construction

MAG 200S: Standardized, available at short notice

12-30 VDC

HTL or TTL

MAG individual:

up to 200.000 ppr (depending on the outer diameter of the pulse wheel)

MAG 200S:

up to 32.768 ppr

0° and 90° track, reference pulse, check output and inverted signals

MAG individual:

Depending on design / max. 200 kHz (higher frequencies on request)

MAG 200S:

4000 rpm / max. 200 kHz

MAG individual:

MAG 200S:

MAG individual:

MAG 200S:

MAG individual:

MAG 200S:

-40 °C to +85 °C

MAG individual:

IP66 to IP68

MAG 200S:

IP67 to IP68

MAG individual:

Size dependent

MAG 200S:

approx. 2-5 kg

MAG individual:

MAG 200S:

MAG individual:

MAG 200S:

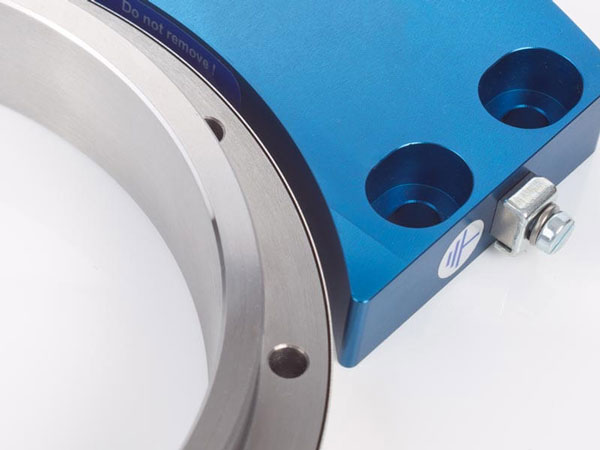

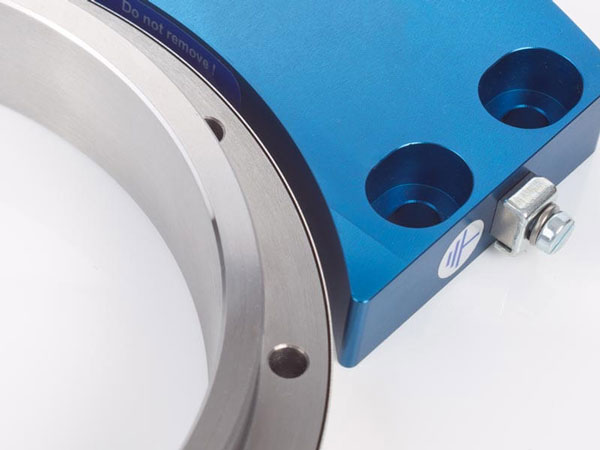

Protection cover made of carbon fiber reinforced plastic (CFRP)

UL/CSA

Take a look at our animations for the steel, crane and port technology, and mining sectors! Click through our animations from a rough overview to the specific mounting location of an encoder and get direct suggestions for suitable encoder solutions.

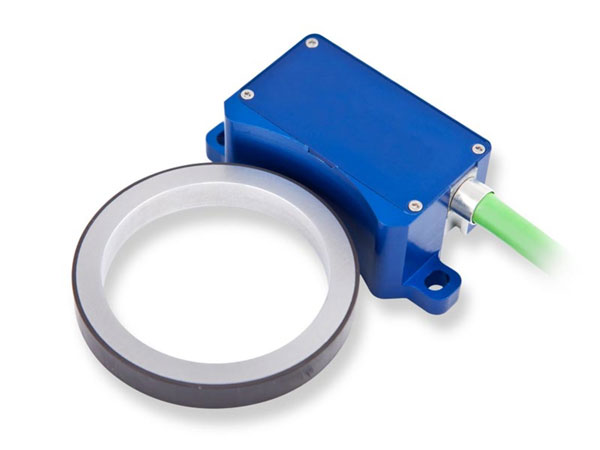

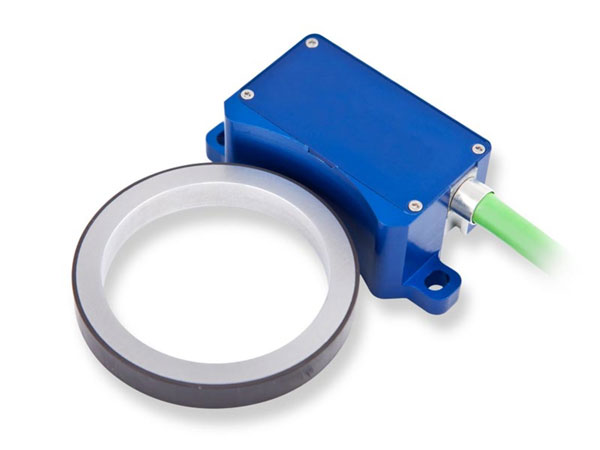

The bearingless magnetic rotary encoders MAG incremental are particularly well suited for mounting situations with very limited space, without a free shaft end or with large shaft diameters of up to approx. 1,350 mm.

Magnetic rotary encoders are insensitive to dust, soiling, external magnetic fields, liquids and condensation (operation in media possible). Additionally, they are bearingless and thus wear-free.

MAG Incremental: bearingless magnetic rotary encoders

Reliable

The MAG incremental magnetic rotary encoders are extremely resistant to external influences such as shock, vibration, dust or liquids and ensure optimal system availability.

Flexible

The MAG bearingless magnetic rotary encoders are suitable for a large number of applications and mounting situations.

Tailor-made and safe

The MAG bearingless magnetic rotary encoders are designed, adapted and manufactured for the respective application.

Split pulse wheel: ideal for retrofit projects

The standardized bearingless MAG variant 200S with incremental output signal including reference pulse is available for shafts with a diameter of 50 – 180 mm. MAG 200S offers the optimal compromise between available product options and extra fast delivery time.

Bearingless magnetic rotary encoder MAG 200S at a glance:

Optionally available:

MAG 200S: bearingless magnetic rotary encoder with extra fast delivery time

We look forward to your challenges.