Application

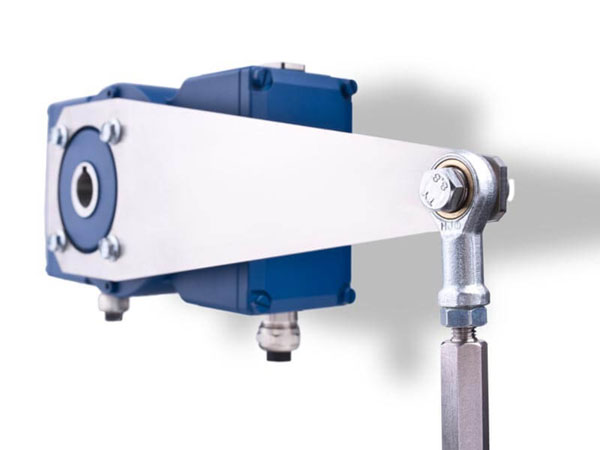

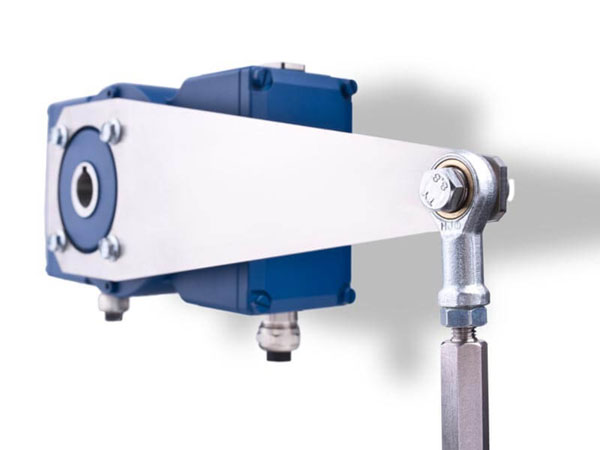

Compensation of smaller mounting inaccuracies of hollow shaft encoders (radial eccentricity of the drive shaft / radial eccentricity resulting from fit tolerances / axial movement of the drive shaft)

For hollow shaft encoder mounting

Compensation of smaller mounting inaccuracies of hollow shaft encoders (radial eccentricity of the drive shaft / radial eccentricity resulting from fit tolerances / axial movement of the drive shaft)

Calculated individually case-by-case /design as per consultation:

Calculated individually case-by-case /design as per consultation

Calculated individually case-by-case /design as per consultation

Calculated individually case-by-case /design as per consultation

Calculated individually case-by-case /design as per consultation

Yes (optional)

Take a look at our animations for the steel, crane and port technology, and mining sectors! Click through our animations from a rough overview to the specific mounting location of an encoder and get direct suggestions for suitable encoder solutions.

Torque brackets compensate for tolerances due to radial eccentricity of the drive shaft, radial eccentricity resulting from backlash and axial movement of the drive shaft when mounting hollow shaft rotary encoders. They are equipped with maintenance-free and corrosion-resistant high-performance link heads and torque bracket rods. Lever length and mechanical interface are customized to meet application requirements.

Optionally, the torque brackets are also available as certified safety components.

We look forward to your challenges.